After building a stand for my3D printer, I also quickly realized that I also needed to have some sort of small workshop space in the house.

Now don't get me wrong, I am still going to have the "big" shop, however, it is a few miles down the road from my house, and sometimes, it's just not worth the trip if I have some sort of quick or small project that needs to be done.

My 3D printer is currently sitting comfortably on its stand in a corner of my family room. Looking at where I have it located, I noticed that I just had enough space beside it for a little work area and I did have a fair bit of scrap wood pieces leftover that was still looking to be put to good use.

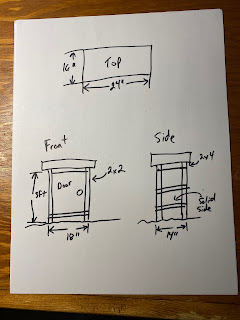

Looking at the space around the 3D printer, I figured that I could put it in a small work area that would be about 2 feet wide and 16 inches deep. While not a lot of space, it should be sufficient for the small projects that I had in mind.

I also wanted to make the workbench something that could more or less blend into the family room, meaning that I wanted to make it look more like a cabinet, allowing for the storage of tools and supplies within the workbench, hidden away from sight.

Due to its small size, this would make a very nice accessory for someone who lives somewhere like an apartment, but would like to have their own dedicated "shop space".

Based on the space restrictions that I had to work with and the materials that I had on hand, I did up a quick sketch of the design for my workbench

The workbench will utilize a combination of 1 X 5 pallet deck boards in addition to 3/4 inch thick plywood strips for the bulk of the construction. The main support of the workbench will be handled with some 2 X 2 pine posts that I had on hand from another project that I had started a long time ago but had since abandoned for some reason.

To start the build, I first focussed on the business end of the workbench - the top.

I first took 4 pallet deck boards. After I planed them down to remove the rough surfaces, I cut them to a length of 22.5 inches. After that, I applied some glue along the edges of the boards and clamped them together so that I got a 22.5 X 18 board.

After the glue had dried, I trimmed the board to 22.5 X 14.5.

The next step was to further strengthen the support legs of the workbench. To do this, I first cut out some 2 inch wide strips of plywood.

After that, I did the following:

- Cut three 22.5 inch long strips and attached them to the workbench supports where what will be the back of the workbench, one strip was attached to the supports just underneath the top of the workbench, one strip was attached 2 inches above the bottom of the supports and the third strip was attached 16 inches from the bottom strip.

- Next, I cut two 22.5 inch long strips and attached them to the workbench supports where what will be the front of the workbench, one strip was attached to the supports just underneath the top of the workbench, with the other strip attached 2 inches above the bottom of the supports

- After that, I cut four of the strips to a length of 14.75 inches and attached them to each of the "short" sides of the workbench supports, overlapping them with the strips that I had attached to the back of the workbench

No comments:

Post a Comment